In the competitive world of flooring solutions, innovation and reliability are paramount. Qingdao Eaststar Plastic Machinery Co., Ltd. proudly introduces its state-of-the-art PVC/PE WPC Flooring Equipment, designed to revolutionize the production of durable, eco-friendly flooring materials. This advanced machinery caters to the growing demand for high-performance flooring that combines aesthetics with sustainability, making it an indispensable asset for modern manufacturing facilities.

PVC/PE WPC Flooring Equipment Overview" />

PVC/PE WPC Flooring Equipment Overview" />

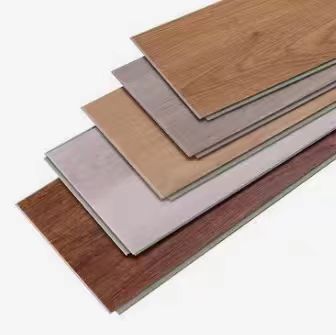

Imagine a production line that effortlessly transforms raw materials into beautiful, resilient flooring. The PVC/PE WPC Flooring Equipment does just that, utilizing cutting-edge technology to process polyvinyl chloride (PVC), polyethylene (PE), and wood-plastic composites (WPC) into versatile flooring products. Whether for residential, commercial, or industrial applications, this equipment ensures consistent quality, enhanced durability, and stunning visual appeal. Its primary function is to streamline the extrusion and molding processes, enabling manufacturers to produce flooring that withstands heavy foot traffic, moisture, and daily wear while maintaining an elegant finish.

What sets this equipment apart are its core advantages. Engineered with precision, it incorporates high-grade materials and innovative mechanisms that boost efficiency and reduce operational costs. The intelligent control systems allow for seamless adjustments, ensuring optimal performance with minimal manual intervention. Additionally, the equipment is built to last, with robust construction that minimizes downtime and maintenance needs. Users benefit from a smooth, automated workflow that maximizes output without compromising on quality. Qingdao Eaststar Plastic Machinery Co., Ltd. stands behind every unit with rigorous testing and a commitment to excellence, providing peace of mind through reliable after-sales support and comprehensive warranties.

Many manufacturers face challenges like inconsistent product thickness, high energy consumption, and frequent machine breakdowns. These issues can lead to wasted materials, increased costs, and delayed deliveries. With the PVC/PE WPC Flooring Equipment, such pain points are effectively addressed. The machinery features precision extrusion technology that maintains uniform thickness across all products, while energy-efficient motors reduce electricity usage by up to 20%. Its durable components, such as hardened screws and barrels, resist wear and extend the equipment's lifespan. Below is a summary of key parameters that highlight its performance capabilities:

| Parameter | Specification |

|---|---|

| Output Capacity | Up to 500 kg/h |

| Power Consumption | 30-50 kW (depending on model) |

| Max. Operating Speed | 15 m/min |

| Material Compatibility | PVC, PE, WPC blends |

| Noise Level | < 75 dB |

This equipment is ideal for flooring manufacturers, construction companies, and DIY enthusiasts looking to produce high-quality, sustainable flooring. It excels in various settings, from large-scale factories to small workshops, enabling users to create products for homes, offices, retail spaces, and outdoor areas. By investing in this machinery, businesses can expand their product lines, meet eco-friendly standards, and cater to clients who value durability and style.

Using the PVC/PE WPC Flooring Equipment brings a sense of accomplishment and confidence. Manufacturers no longer worry about subpar outputs or frequent repairs; instead, they experience smoother operations, higher profitability, and the ability to offer innovative flooring solutions that impress customers. This equipment solves common industry problems like material waste and inefficiency, transforming production floors into hubs of creativity and reliability. Clients often report feeling empowered to take on larger projects and explore new market opportunities, thanks to the consistent quality and versatility of the flooring produced.

When compared to other flooring machinery, the differences are clear. Unlike conventional extruders, this equipment integrates smart automation for real-time monitoring and adjustments, reducing human error. Its compatibility with a wide range of materials, including recycled plastics, supports sustainability goals without sacrificing performance. Moreover, the modular design allows for easy upgrades and customization, ensuring it adapts to evolving industry trends. Qingdao Eaststar Plastic Machinery Co., Ltd. emphasizes user-centric features, such as ergonomic controls and low-noise operation, making it a standout choice in the market.

Frequently Asked Questions:

What types of flooring can I produce with this equipment?

You can manufacture a variety of flooring products, including rigid PVC tiles, flexible PE sheets, and wood-plastic composite boards suitable for indoor and outdoor use. The equipment supports customization in terms of colors, textures, and dimensions, allowing for creative designs that meet specific client needs.

How easy is it to operate and maintain the machinery?

The equipment is designed for user-friendly operation, with intuitive interfaces and automated controls that require minimal training. Regular maintenance involves simple steps like cleaning and lubrication, and comprehensive manuals and support from Qingdao Eaststar Plastic Machinery Co., Ltd. ensure smooth upkeep.

Can it handle recycled materials effectively?

Yes, the PVC/PE WPC Flooring Equipment is optimized for processing recycled PVC, PE, and wood fibers, promoting eco-friendly production. It maintains consistent quality even with varying material compositions, helping reduce environmental impact while cutting costs.

What is the typical lead time for delivery and installation?

Delivery times vary based on order volume and location, but generally range from 4 to 8 weeks. Installation services are available, with expert technicians assisting to ensure the equipment is set up correctly and operational quickly.

Does the equipment come with a warranty?

Yes, Qingdao Eaststar Plastic Machinery Co., Ltd. offers a standard warranty covering parts and labor for one year, with options to extend. This commitment to quality ensures long-term reliability and customer satisfaction.

In summary, the PVC/PE WPC Flooring Equipment from Qingdao Eaststar Plastic Machinery Co., Ltd. embodies innovation and practicality. It empowers users to create superior flooring products that align with modern demands for sustainability and performance. By choosing this machinery, you invest in a future where production is efficient, products are exceptional, and business growth is within reach.